What to Know When Selecting Commercial Bar Stools

Selecting commercial bar stools goes far beyond appearance. In restaurants, bars, lounges, bowling centers, and public venues, bar stools are subjected to constant use, movement, and heavy weight loads. One of the most critical—and often overlooked—decisions buyers must make is choosing between metal frames and wood frames, as this directly impacts safety, durability, and liability.

Seat height remains the first technical consideration. Commercial bar stools are generally designed for either counter-height applications (24"–26" seat height for 36" counters) or bar-height applications (29"–31" seat height for 42" bars). Incorrect seat height leads to discomfort, poor posture, and guest dissatisfaction, regardless of stool quality.

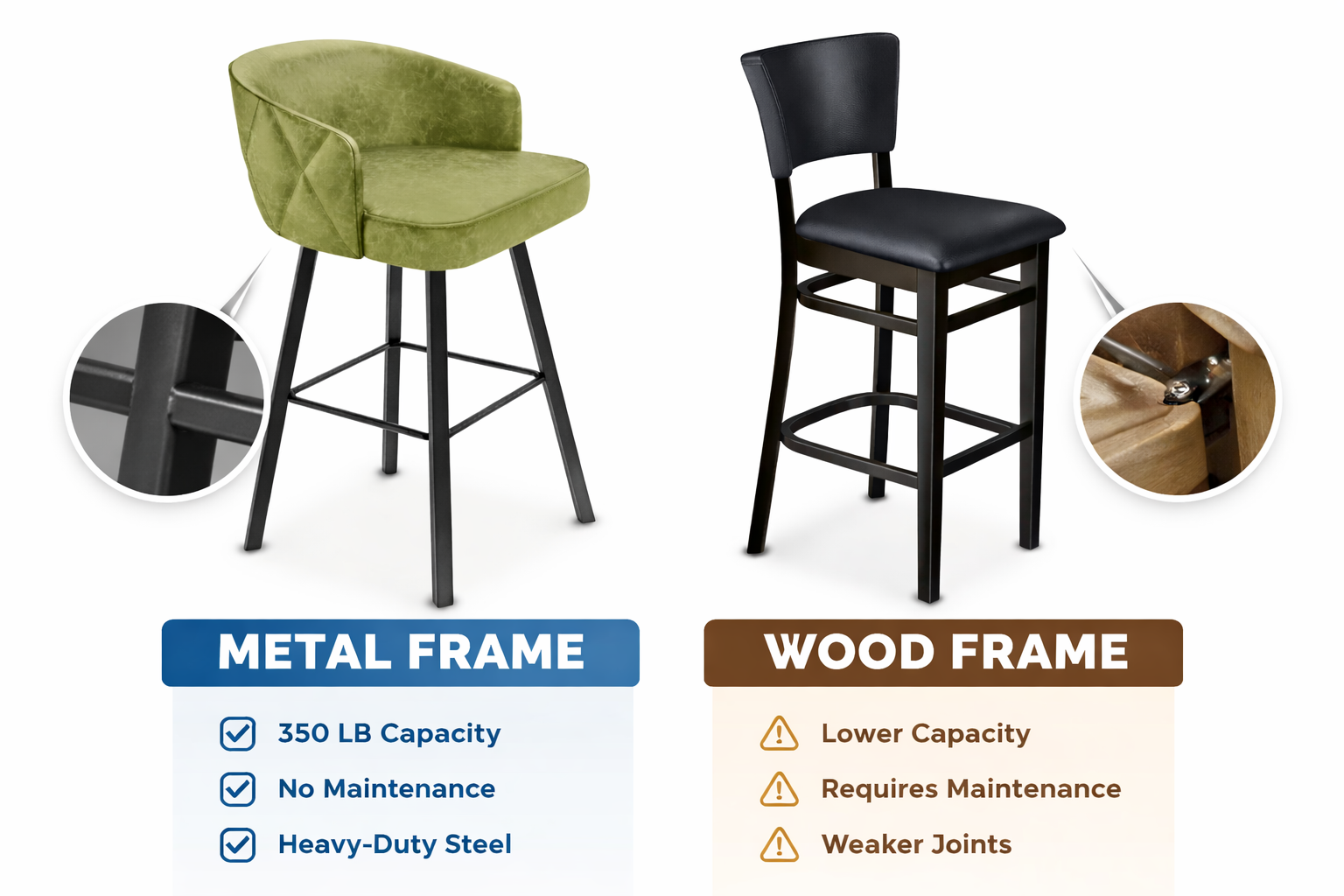

Frame construction, however, is where the most significant differences appear. Metal-framed bar stools are strongly recommended for commercial use due to their superior strength, stability, and weight capacity. Properly engineered metal stools are typically rated for 350 lb weight capacity per seat, making them suitable for a wide range of guests while minimizing risk. Metal frames do not loosen over time, do not crack, and are not affected by humidity or temperature changes commonly found in food and beverage environments.

Wood-framed bar stools, while visually appealing, are far more susceptible to wear in commercial settings. Wood joints can loosen, frames may shift, and finishes often require ongoing maintenance. Over time, this can lead to instability, increased service calls, and potential liability concerns. In high-traffic venues, wood stools often need frequent tightening, repair, or replacement—adding long-term cost and operational disruption.

Another advantage of metal frames is low to zero maintenance. Commercial metal stools require no retightening, no joint reinforcement, and no structural upkeep. This reliability is especially important in busy facilities where staff cannot monitor seating daily. Metal frames also maintain consistent performance even when stools are frequently moved, pushed, or repositioned.

Upholstery and seat materials should also meet commercial standards. Fire-rated finishes, high abrasion resistance, and easy-to-clean surfaces are essential. When paired with a metal frame, these materials create a stool that performs reliably year after year.

Back design plays a supporting role. Backless stools allow quick turnover and easy circulation, while stools with backs encourage longer seating and greater comfort. Regardless of back style, the frame must support constant movement and repeated loading without compromising stability.

From a liability standpoint, metal-framed commercial bar stools offer the safest solution. High weight capacity, structural consistency, and maintenance-free performance help keep risk close to zero—something every facility owner and operator should prioritize.

Key Questions Answered

Q: Why are metal frames better than wood for commercial bar stools?

Metal frames provide higher weight capacity, long-term stability, and eliminate joint loosening common with wood frames.

Q: What is the recommended weight capacity for commercial bar stools?

A minimum of 350 lb per seat is recommended for commercial environments.

Q: Do metal bar stools require maintenance?

No. Properly built metal stools require virtually no maintenance and do not need retightening or structural repair.

Q: Are wood bar stools suitable for high-traffic venues?

Wood stools may work in light-use settings but are not ideal for high-traffic commercial spaces due to maintenance and liability risks.

Q: Does frame material affect liability?

Yes. Metal frames significantly reduce the risk of structural failure, helping keep liability exposure near zero.