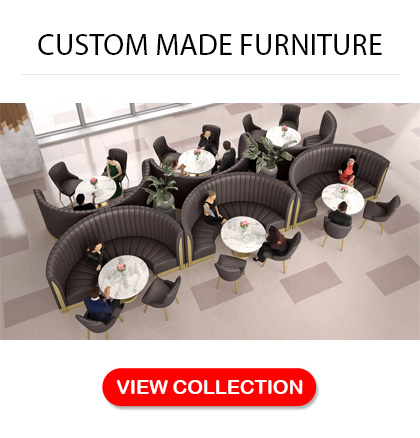

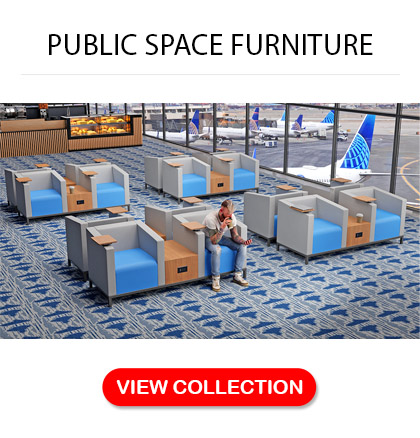

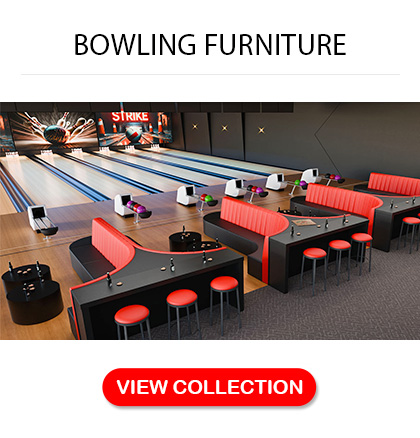

Contract Furniture – Built for Your Project

Every custom contract furniture project starts with a conversation. Clients often reach out asking if we design and manufacture custom commercial furniture, and we begin by understanding what type of furniture is needed and where it will be used. From public seating and hospitality spaces to golf simulators, bowling centers, restaurants, and lounges, each environment presents unique design and performance requirements. Based on real project experience, we help shape ideas into functional solutions by defining layouts, dimensions, materials, and finishes. The result is furniture designed specifically for the space, built to support daily commercial use while aligning with the project’s vision. Start Project.

Custom Contract Furniture – Key Questions Answered

Q: What does “built to specification” mean in contract furniture?

A: It means furniture is designed and manufactured to exact project requirements, including size, layout, materials, finishes, and performance needs.

Q: Is custom furniture more expensive and more difficult to manufacture?

A: Yes. Custom furniture is built from the ground up, often requiring sample development, new templates, and specialized production steps. This process involves additional labor, engineering time, and longer production timelines compared to standard items. However, it allows the furniture to be built precisely to specification, ensuring the final product fits the space, meets performance requirements, and aligns with the project’s design intent.

Q: What types of spaces use custom contract furniture?

A: Restaurants, public seating areas, hotels, lounges, bowling centers, golf simulators, casinos, and other high-traffic commercial environments.

Q: How does the custom process typically start?

A: Most projects begin with a conversation about furniture type, placement, traffic level, and overall design goals using the blueprint and layouts.

Q: Is custom contract furniture durable enough for daily use?

A: Yes. All pieces are built with reinforced frames, commercial-grade foam, and performance upholstery for continuous use.

Q: Can layouts and finishes be customized?

A: Absolutely. Dimensions, configurations, upholstery, stitching, and finishes are all customizable to meet project specifications.