Why U.S. Commercial Furniture Manufacturing Is the Minority — And Why It Matters More Than Ever

In today’s rapidly changing hospitality industry, one truth has become impossible to ignore: commercial furniture manufacturers in the United States are a rare breed. Not many factories truly specialize in producing hospitality-grade, restaurant-grade, and contract seating that is genuinely Made in the USA.

Many companies position themselves as “manufacturers,” yet in reality they simply import finished products from overseas, bolt on a few parts, and ship them out. Only a small handful of authentic American factories continue to design, engineer, cut, sew, upholster, and build furniture on U.S. soil. As highlighted in Manufacturing Today Magazine this difference is exactly what separates real domestic manufacturers from import-driven resellers.

“A lot of companies bring products from overseas — but very few are actually making things happen in the U.S.,” says CEO Vlad Spivak.And that reality shapes everything about quality, speed, customization, and customer satisfaction.

The Honest Truth: Imports Control the Majority of the Market.

While exact numbers vary by category, industry research and trade reports consistently show that U.S. commercial furniture manufacturers make up only a small share of total products sold in the country. In many segments—especially restaurant seating, club furniture, public-space furniture, and hospitality case goods—domestic manufacturers represent an estimated 25% or less of all production.

Meaning 75% or more of what lands in restaurants, bars, hotels, casinos, and lounges across America is imported.This imbalance didn’t happen overnight. It grew from outsourcing, low labor costs overseas, long supply chains, and companies choosing the “easy” route: buy from another country, resell it, and avoid investing in real factories. But that shortcut comes at a price — and hospitality operators feel it every day.

Why Overseas Manufacturing Often Fails the Hospitality Industry

The hospitality world is fast, demanding, and unforgiving. Projects move quickly, changes happen overnight, and opening dates are non-negotiable. When facility owners and managers need furniture, they need:

-

Custom sizes

-

Custom colors

-

ADA-compliant dimensions

-

Quick turnaround

-

Fire-rated materials

-

Commercial durability

-

Consistent quality

-

Real accountability

These requirements are nearly impossible for overseas production to handle reliably.

When working with import-based suppliers, customers often face:

-

No control over production timelines

-

Delays at ports and customs

-

Uncertain material quality

-

Inconsistent craftsmanship

-

No guarantee products meet U.S. standards

-

Zero recourse when something arrives damaged

“How can you help your customer today if you’re waiting for a container you can’t control?” says Vlad Spivak. “Fast-moving industries cannot rely on slow-moving oceans.”

Hospitality projects must hit deadlines. Restaurants cannot delay openings. Clubs and casinos cannot push back events. Designers cannot risk failed installs.

And yet, the majority of the market depends on imports.

Why U.S. Manufacturers Matter More Than Ever

“We understand the urgency behind every project,” says Sales Manager Jennifer Perez. “Every business has a story. Every grand opening has a deadline.”

This is exactly why American manufacturers like Modern Line Furniture maintain significant advantages over importers.

Inside our Factory the difference is clear:

Materials are stocked on-site Upholstery, foam, wood, laminates, HDPE, and hardware are already available — no waiting months for shipments.

CNC cutting eliminates delays.Precision cutting of wood, foam, and upholstery ensures perfect consistency and fast production.

Automated sewing and upholstery.This ensures clean lines, tight fit, and uniformity across all pieces — something inconsistent in overseas operations.

Production flow is optimized for fast ETAs.Furniture can be produced in 2–4 weeks, not 12–18 weeks like imports.

Quality control happens before shipping.Not at a port. Not in a warehouse.Right inside the factory — where it matters.This is the true meaning of Made in the USA.

Customization Is Where Imports Collapse

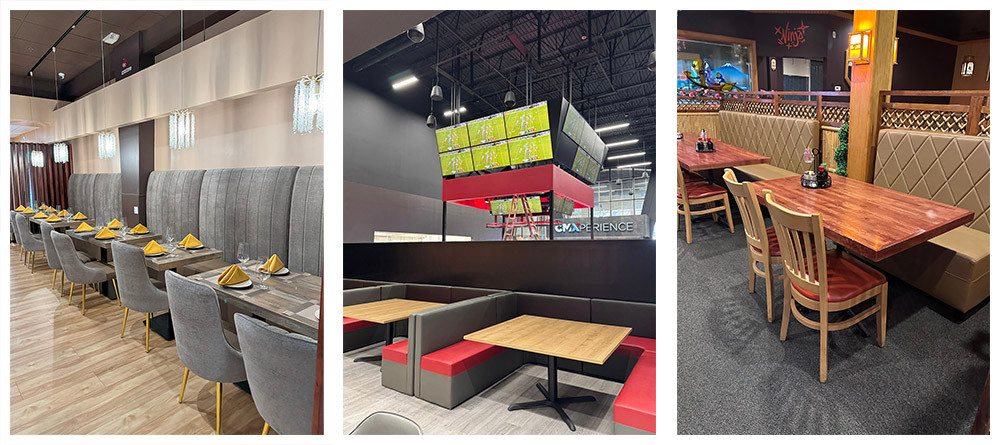

Restaurants, nightclubs, universities, casinos, golf simulators, and public spaces increasingly demand custom-fit furniture:

-

Booths built to exact lengths

-

Modular seating tailored to floorplans

-

Specialty laminates

-

Two-tone upholstery

-

Privacy walls

-

ADA options

-

Power-ready seating

-

High-abrasion fabrics

-

Hospitality construction standards

For importers, this creates major bottlenecks. For U.S. manufacturers, customization is part of the daily workflow.

Modern Line Furniture produces custom commercial-grade furniture at scale, and that is one of the reasons we remain part of the top-tier American manufacturers today. The U.S. Manufacturing Shortage: A Real Problem for the Industry

“With today’s market, the percentage of true U.S. manufacturers who want to make a difference — versus those chasing quick overseas deals — is shrinking,” says Jennifer Perez.

“We are short on real American factories, and we need more to support customers around the country.”

The reality is clear:

-

Imported furniture dominates the market.

-

Domestic commercial furniture factories are the minority — likely 25% or less.

-

Quality-focused U.S. manufacturers are essential to the hospitality industry.

Modern Line Furniture stands strong among that small group. We continue to invest in U.S. machinery, skilled labor, custom fabrication, and fast delivery — because our customers depend on it.

When the industry needs speed, durability, customization, consistency, and reliability, they turn to American manufacturers — not containers.