Why Do Some Companies Deliver Restaurant Furniture Faster Than Others?

The Real Story Behind Lead Times, Shipping Delays, and Domestic Manufacturing

If you're in the restaurant or hospitality business, you’ve probably come across this frustrating situation:You find a great booth or table online. You request a quote. And then—boom—you’re told the delivery time is 12 to 14 weeks.Yet another company tells you they can deliver in just 3–4 weeks.Same product category. Same industry. So why the massive gap?

This question is one we get all the time at Modern Line Furniture, and the answer is simpler than you might think.The real difference lies not in the product—but in the process.

And it all begins inside the factory walls.

The Hidden Factor: Where Your Furniture is Actually Made ? When restaurant owners shop online for booths, tables, chairs, or lounge seating, they’re often looking at images, prices, and styles. But there’s one thing you won’t see in the product photo:

Where is it actually being manufactured?

Most companies won’t tell you outright. But here's the truth:

-

A company quoting 12–14 weeks is likely importing that product.

-

A company quoting 3–4 weeks is almost certainly manufacturing it themselves—right here in the USA.

At Modern Line Furniture’s factory, we handle everything under one roof: design, CNC cutting, upholstery, assembly, and packaging. This allows us to eliminate overseas shipping delays, miscommunications, and customs hold-ups.

The Risk of Buying Furniture That’s “On the Water”

If you're working with a company that imports furniture, what you're really getting is a promise—a promise that the container from overseas will arrive on time, clear customs without issues, and deliver to your job site without any unexpected delays.

But in today’s global shipping environment, that’s a lot of “ifs.”

Whether it’s:

-

Delays at foreign ports

-

Unpredictable weather at sea

-

U.S. customs inspections

-

Container shortages

-

Or global disruptions like tariffs or labor strikes

…your project timeline can unravel quickly.

And when you're outfitting a new restaurant or updating a busy bar, you simply don’t have time for that kind of uncertainty.

What Happens Inside a U.S. Factory Makes All the Difference

Let’s take a closer look at what makes domestic manufacturing more efficient:

1. CNC Machinery: The Game Changer

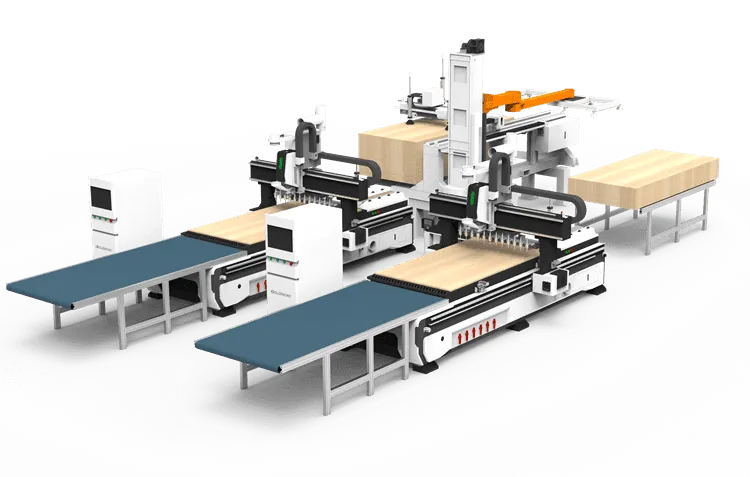

Modern Line Furniture has invested in state-of-the-art CNC equipment—automated machines that cut wood panels, curved shapes, and complex seating elements with extreme precision.

A CNC machine doesn’t get tired. It doesn’t make measurement errors. And it doesn’t rely on a shipping container to show up.

In fact, CNC technology allows us to:

-

Cut dozens of booth panels in minutes

-

Eliminate human error and material waste

-

Streamline repeat orders with digital templates

-

Produce consistent shapes for fast, uniform assembly

This is a massive time-saver. The wood that makes up your booth or table can be cut and prepped on the same day the order is received. That’s not a luxury importers can offer.

2. In-House Assembly Line Workflow

Once the materials are cut, they flow directly into our assembly and upholstery departments—without leaving the building.

Our facility operates like a well-oiled machine:

-

CNC cutting → sanding → framing → upholstery → quality check → packing → loading dock

All within one building.

That’s how we’re able to create complex custom booths, U-shape sectionals, or bar-height communal tables faster than companies relying on offshore manufacturing.

3. Human Touch Where It Counts

Automation is powerful—but craftsmanship still matters. While machines prep the materials, our team of experienced upholsterers and assemblers put it all together by hand, ensuring quality and durability in every product we ship.

This balance of technology + skilled labor is the winning formula for efficiency.

At Modern Line Furniture, we don’t rely on overseas schedules. We rely on our own team, our own technology, and our own factory.

This means:

-

Shorter, reliable lead times

-

Fewer delays or surprises

-

Customized products made to order

-

Real-time updates and communication

-

Pride in U.S. manufacturing

Whether you’re ordering restaurant booths, tables with power outlets, or hospitality lounge seating, we build your furniture to order and on time.

What This Means for You

If you’re outfitting:

-

A new restaurant franchise

-

A high-end bar with bottle service VIP seating

-

A hotel lobby with modular lounge furniture

-

Or a campus café with communal tables…

…you can’t afford to wait months for overseas shipments.

With Modern Line Furniture, your project is in good hands—with fast lead times, transparent communication, and high-quality U.S.-made results.

Final Thoughts: Don’t Gamble with Your Timeline

When choosing a furniture supplier, ask what’s behind the timeline.

Are they quoting 3–4 weeks because they make it? Or are they quoting 14 weeks because they’re waiting for a boat?

Now you know the difference.

Want a tour of our facility?

Want a tour of our facility?

See how we build fast, reliable, and American-made furniture:

Explore the Factory →

Ready to build your next space with confidence?

Ready to build your next space with confidence?

Explore our restaurant seating collection or contact us directly for a custom quote.